Acoustic Tank

Measurement of noise radiated by structures. Optimization of structural details to reduce noise radiation. Determination of oscillation frequencies and mode shapes of hulls and structural components.

Main data:

length — 5 m

width — 3 m

depth — 3 m

Anechoic Basin

Experiments on models of sonar domes sized 1.5×1.3 m2 (weight up to 2 tons) in frequency bands from 0.5 to 10kHz to study dome performance in reducing own ship noise.

Measurement of reflection, absorption and loss factors on test samples at different incidences of plane acoustic wave, as well as investigation of acoustic processes in submerged machinery and equipment.

Main data:

Length, m — 25.0; Diameter, m — 4.0

Hydrostatic pressure, MPa — 0–3.0

Maximum size of test samples, m — 1.8×1.4×1.0

Test facilities for resilient mounts

Investigation of static & dynamic stiffness and strength of

Impact testing machine for

Weight — 27…1500 kgf

Nominal static load — from 10 to 10000 kgf

Initial deformation velocity under drop weight, m — 1…6 m/s

Max. size of test samples — 700×350×200 mm

Impact tests of

Anechoic Chambers

Certification tests of equipment, vibration isolation & absorption tools. Investigation of machinery and equipment as sources of

The anechoic chambers with auxiliary equipment are used to determine:

Test facility for investigation of vibration & acoustic characteristics of powerplant modules and their components

Main functional & technical specifications:

Slotted

Dynamic range — 120 dB

Frequency band — 2 Hz–12800 Hz

Pipeline test rigs

Total pipeline length — over 100 m

Inner diameter of pipes from 50 to 150 mm

Volume of water tanks — 50 m3

Water flow rate in pipes from 0.1 to 7 m/s

Max. hydrostatic pressure in pipelines at least 1 MPa with fluctuations within 10 min not more than 1%

Acoustic and vibration fields, dynamic characteristics of systems and their components are determined in the frequency range from 2 tо 12800 Hz.

Test rig for investigation of pipeline details

Investigation of hydrodynamic, cavitation and vibration & acoustic characteristics of hydraulic system details (fittings, mufflers, jet pumps, etc.) and components containing gas/liquid mixtures.

Main data:

Working pressure — up to 5 MPa

Water flow rate — up to 250 t/hour

Diameter of tested elements — up to 200 mm

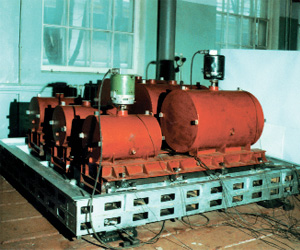

Rotor and balancing rig

The test rigs help to reduce vibrations at the rotor rotation frequency by 15 to 20 dB and increase the service reliability.

Balancing and investigation of dynamic characteristics of:

Main data:

max. rotor length — 5 m

mass — up to 3 t

max. rotor diameter — 2 m

max. spacing between supports — 2.8 m

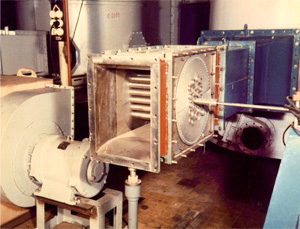

Air filtering rig

Development and tests of standard air filtering systems.

Evaluation of air filtering systems for removing salt, sand and dust particles.

Small aerodynamic rig

Investigation of vibration excitation in tube bundles of heat exchanges, determination of optimum flow parameters

Analytical & experimental of hydraulic and hydrodynamic characteristics of power plant equipment and their optimization.

Main data:

Measurement range of flow rate, m3/s — 0–1.5

Measurement range of pressure, Pa — 0–1100

Investigation of velocity & pressure fields in air channels of various fan types to produce

Main data:

Impeller model diameter, m — 0.5

Motor output, kW — 177

Range of measured flow rates, m/s — 0–12

Range of measured pressures, Pa — 0–22000

Rotor rpm — 0–4000

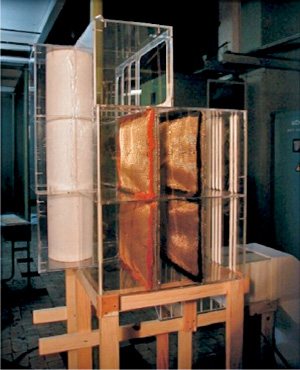

Active noise cancellation rig

Investigation of active noise suppression techniques for noise reduction in rooms and compartments.

Development of control algorithms for active noise cancellation technologies.

Main data:

Noise suppression frequency band — 100–300 Hz

Spectrum type of suppressed noise — discrete or continuous

Efficiency — 12–16 dB for discrete components; 5–7 dB in octave band

Hydroacoustic tunnels

Investigation of sound insulation and reflection of materials and structures on cylinder specimens of 50, 70, 150 mm in diameter under hydrostatic pressures up to 70 MPa, at specified temperatures in the range of 2–20°С.

Measurement of sound reflection frequencies (within 1–20 kHz) on specimens placed in water.

Sea test rig with

The

These experiments are helpful for optimization of tools for effective attenuation of hydrodynamic noise in realistic environment. Without machinery and propulsors we can take measurements at minimum interferences and low background sea noise.

Accelerated shock mount tests

Hydraulic test rig for service life tests under

Frequency range — 0.1–0.7 Hz

Strain amplitude — 2–50 mm

Test force — up to 45000 kgf

Max. size of tested vibration isolators — 700×350×200 mm

This rig provides accelerated lifetime test modes producing equivalent realistic service loads due to increased strain amplitudes.

Vibration frequency range — 15…20 Hz

Vibration amplitude — 0.1…2.0 mm

Rated load on test objects — up to 2000 kgf

Max. size of tested objects — 400×400×300 mm

This rig provides accelerated lifetime test modes equivalent to real service environment using higher strain frequencies.

Reverberation chamber:

Internal space, m — 9.4×7.1×4.5

Volume, m3 — 300

Test frequency range, Hz — 100–10000

Interference level, dBA — 40

Max size of test object, m — 1.5

Anechoic chamber:

Free space, m — 10×9×5

Volume, m3 — 450

Test frequency range, Hz — 100–10000

Interference level, dBA — 25

Max size of test object, m — 1.5

Volume of test object, m3 — 2.0

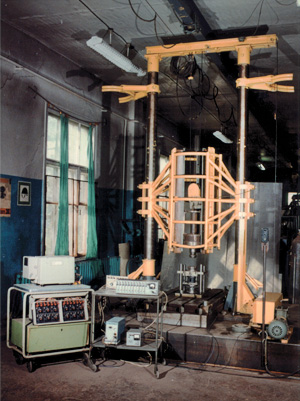

Test rig for determination of mechanical & acoustic impedances of vibration isolators and noise mufflers

This facility is intended for experimental determination of complex & energy input and transfer mechanical and acoustic impedances of vibration isolation and noise suppression tools used in machinery, equipment and hydraulic pipelines or air ducts, it also enables researchers to determine the loss coefficients of vibration isolation structures.

This facility is equipped with:

A 12 m2

Frequency range: from 5 tо 10000 Hz.

The complex & energy input and transfer impedances can be measured in axial and transverse directions:

Impact test machines

Impact strength investigation of shipboard equipment

Software package for processing and analysis of test data

Main specifications:

Load lifting capacity, t — 0.2 (0.5)

Max amplitude, g — 10–3000 (10–300)

Duration, ms — 100–1 (40–5)

Pulse shape — complex (